Improved Production Throughput

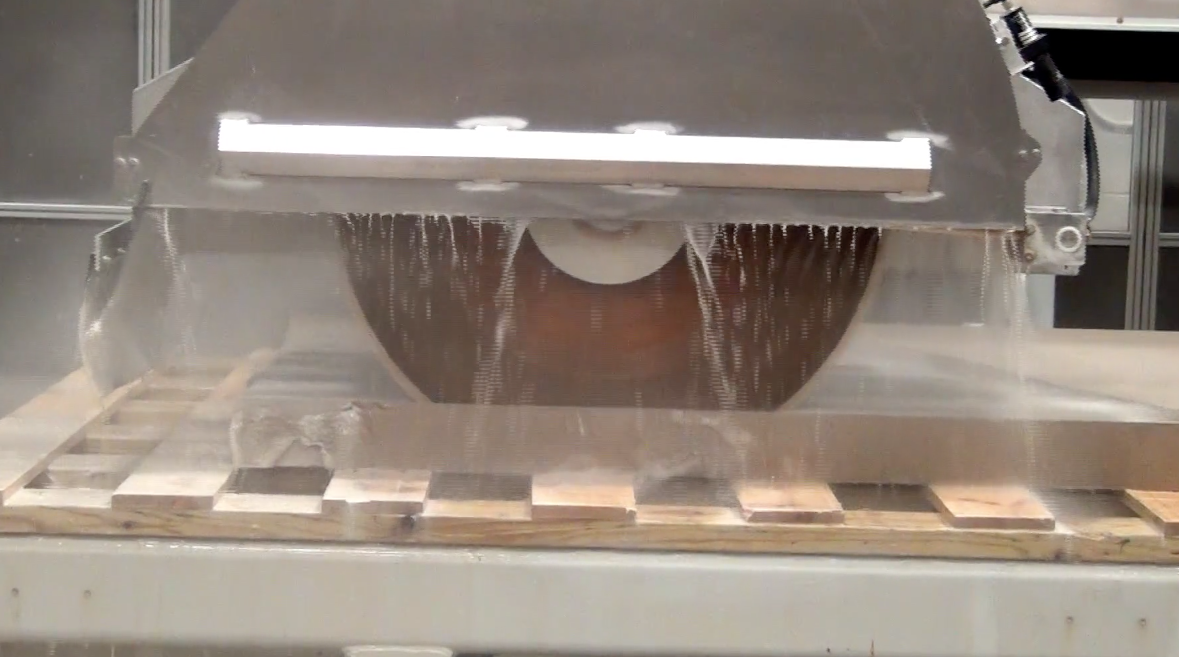

A custom-designed APEX 5-Axis CNC stone-cutting machine, the first of its kind to be produced, was installed and became operational Sept. 1 at the Bloomington, Ind. headquarters of limestone fabricator 3-D Stone. The computer-controlled device, custom prepared by Park Industries of St. Cloud, Minn., is expected to produce a 20-percent increase in 3D Stone’s overall production throughput.

The new device will cut more intricate pieces of stone at twice the speed of predecessor machines, said 3D Stone President Kurt Sendek. It features a vacuum handling system to speed cutting and moving limestone product

The new device will cut more intricate pieces of stone at twice the speed of predecessor machines, said 3D Stone President Kurt Sendek. It features a vacuum handling system to speed cutting and moving limestone product

Improved Design Capabilities

According to Park Industries, movements of the APEX 5-Axis stone cutter are extremely accurate because of its precision-profiled linear way and bearings. The machine’s 5-axis capabilities enable it to make curves with contour cutting, produce straight line and curved profiling, and rapidly process five sides of a stone with a single setup. The APEX can make cuts up to 16″ with a 44″ blade.

“We anticipate significant productivity gains in very short order,” Sendek said. “In addition to enabling us to work faster, the new APEX will help us give our customers more intricate detailed work at a lower cost.”

Sendek said his company has hired a specialist programmer; Park is now training the next generation of CNC operators for 3D Stone.

“We anticipate significant productivity gains in very short order,” Sendek said. “In addition to enabling us to work faster, the new APEX will help us give our customers more intricate detailed work at a lower cost.”

Sendek said his company has hired a specialist programmer; Park is now training the next generation of CNC operators for 3D Stone.